The Myth of the Tiger II’s “Porsche” and “Henschel” Turrets

The Tiger II was built with two different turrets that are often referred to as “Porsche” and “Henschel” turrets, under the assumption that the different types were designed by these respective companies. However, these names are historically incorrect, as neither Porsche nor Henschel designed the Tiger II’s turrets.

This mistake runs so deep that it has popped up everywhere over the decades since the war, in books, documentaries, magazines and video games.

Despite having been corrected before this error continues, likely because the turret incorrectly known as the “Porsche” type was initially designed for use on Porsche’s early attempts at a Tiger II.

So, lets clear up this misconception once and for all!

The “Porsche” and “Henschel” Turrets

First, lets look at the two turrets.

The turrets are easily distinguishable from each other. The type incorrectly known as the “Porsche” turret has a curved front, a bulge in the side for the commander and a rear door that was bolted onto the back of the turret.

This version was designed first early on in the Tiger II project alongside the chassis from Porsche, but was difficult to manufacture and was quickly replaced.

The replacement is the type incorrectly known as the “Henschel” turret. This version can be identified by its flat front and more simple shape. It was much easier to make and was fitted to the majority of Tiger IIs.

A Tiger II at the Musée des Blindés, Saumur. This has the production turret that is often incorrectly called the “Henschel” turret.

Neither of these types were actually designed by Porsche or Henschel though. That honour instead goes to the German company Krupp, who also made the turret for the Tiger I.

We repeat: both of the Tiger II’s turrets were designed by Krupp – not Porsche, and not Henschel.

So how did this mistake happen, and what should you call them?

A Tale of Two Turrets

Confusion about the two different turrets fitted to the Tiger II is a result of Germany’s development process for the tank.

When the requirements that would lead to the Tiger II were released, two companies competed against each other to produce a winning design that would be mass-produced.

These two companies were Porsche and Henschel. They were to design the hull and chassis for a new heavy tank that carried the long 8.8 cm L/71 gun

However, as mentioned neither Porsche nor Henschel would design the turret. This would be done by Krupp, an enormous steel and armaments manufacturer for Germany during WWII. A similar arrangement occurred during the Tiger I’s development too, with Porsche and Henschel designing the hulls and Krupp taking care of the turret.

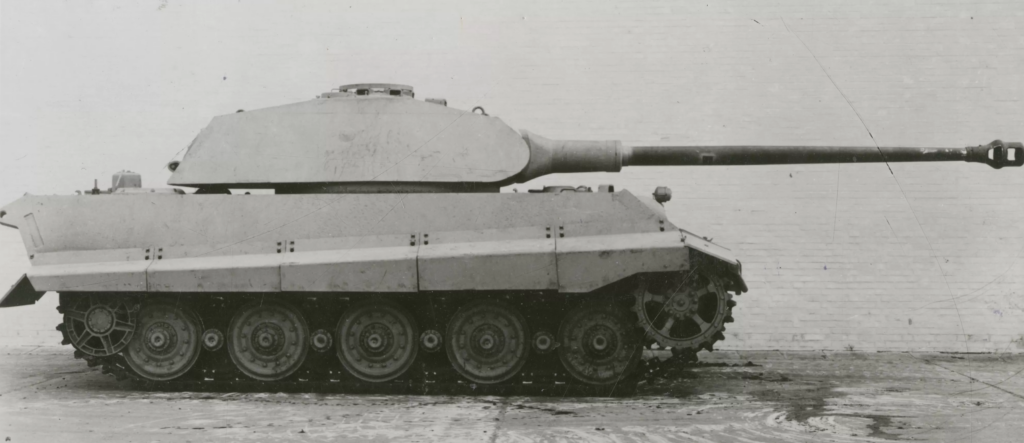

Side view of Krupp’s pre-production turret. Note the curved front of the turret.

For this newer project, Krupp’s turret fit both chassis and would be used on whichever tank won the competition.

Porsche started work on their Tiger II design first, as early as 1942. They began by simply reworking the VK 45.01 (P) (Porsche’s failed alternative to the Tiger I) to carry the long 8.8 cm gun, but new requirements and major modifications resulted in a vastly different design, known as the VK 45.02 (P).

Meanwhile, Krupp designed the turret for this tank. It was very different to previous types, with a low-profile curved front and well-angled sides. This is the version incorrectly known as the “Porsche” type.

In February 1942 an order was made for 100 of Porsche’s design to be produced, along with the accompanying turrets from Krupp. In November 1942 flaw’s in Porsche’s design were found and the order was canceled, but by this time 50 turrets had already been made.

This turret had proved to be extremely difficult to manufacture, with its curved front and sides having to be literally bent into shape, rather than cast or machined.

Front view of the Tiger II pre-production turret. Note the bulge on the right side of the turret. This was to make room for the commander, and was difficult to make.

Krupp redesigned the turret throughout the first half of 1943, creating a flatter shape specifically intended to make production easier and quicker. This is the version incorrectly known as the “Henschel” type.

Henschel had begun work on the Tiger II later than Porsche, and had also tried to rework their previous design (the Tiger I) to fit the long 8.8 cm gun. This would eventually be discarded in favour of a mostly new vehicle, named the VK 45.03 (H).

It was Henschel’s tank that was chosen for production, with the first vehicles being produced before the end of 1943.

But what about the stock of 50 turrets with the curved front? Instead of being scrapped, they were fitted to the first 50 production Tiger IIs. Once these were used up, Tiger IIs were then fitted with Krupp’s newer, simplified turret from June 1944. On the right is a Tiger II with a later production turret. On the far left is a Tiger II with a pre-production turret with the curved front. Image taken in The Tank Museum by Morio CC BY-SA 4.0.

On the right is a Tiger II with a later production turret. On the far left is a Tiger II with a pre-production turret with the curved front. Image taken in The Tank Museum by Morio CC BY-SA 4.0.

This is where the confusion between the two turret types begins, with the first 50 being known as the Tiger IIs with “Porsche” turrets, and the rest being known as the Tiger IIs with “Henschel” turrets.

But now we know they were both in fact designed by Krupp, these names are, at best, misleading.

Today there isn’t a universally accepted name for either of the turrets. We suggest using “pre-series” or “pre-production” instead of “Porsche”, and “series” or “production” instead of “Henschel”.

Pre-Production Turret

The pre-production turret was developed by Krupp alongside the Tiger II project, for use on either vehicle. Although it is the earlier of the two, it actually has a more sleek appearance, with a narrow curved front.

This plate was 100 mm thick, while the sides and rear were 80 mm thick and angled at 30 degrees. The turret roof consisted of three separate plates; one at the front that was 25 mm thick and angled at 77 degrees, one in the center that was 40 mm thick and horizontal, and one at the rear that was 25 mm thick and angled at 80 degrees.

The 50 pre-production turrets built had this roof armor, but the 25 mm plates were cut out and replaced by 40 mm thick plates when they were fitted onto the Tiger II hulls. Interestingly, the Tiger II V2 prototype located at The Tank Museum Bovington still has the 25 mm thick plates.

The first Tiger II prototype (V1) fitted with a pre-production turret. The turret ring was very exposed on this turret, and would be protected by additional shields on vehicles sent into combat.

The first Tiger II prototype (V1) fitted with a pre-production turret. The turret ring was very exposed on this turret, and would be protected by additional shields on vehicles sent into combat.

The rear of the pre-production turret was removable to allow the removal of the 8.8 cm KwK 43 main gun. At the front of the turret were three holes, which housed the MG 34 and binocular gun sight. Above each of these holes is a metal brow that deflected rain drops.

On the left side of the turret is a bulge for the commander. This and the front plate shapes were made by literally bending the steel, a process that proved to be extremely difficult. The front plates in particular were prone to cracking on its curved section.

As intended from the start this turret would have been compatible with both hulls designed by Henschel and Porsche. However, when mounted on Henschel’s hull the turret was fitted with a hydraulic traverse gear. If it had been mounted on Porsche’s hull, it would have been fitted with an electric traverse gear.

Note the rear of this pre-production turret on The Tank Museum’s V2 Tiger II prototype. The large opening at the rear would have had a removable cover. The hole for this component has been blanked over. Image by Morio CC BY-SA 4.0.

Note the rear of this pre-production turret on The Tank Museum’s V2 Tiger II prototype. The large opening at the rear would have had a removable cover. The hole for this component has been blanked over. Image by Morio CC BY-SA 4.0.

In the end though the pre-production turret was simply too complex and time consuming to produce, and was considered unsatisfactory.

The turret was fitted to the first 50 Tiger IIs. Only a single example survives today at The Tank Museum, Bovington.

Toward the end of 1942 there were discussions to update the design with a priority on simplicity of manufacture. This resulted in the most common turret fitted to the Tiger II.

Production Turret

Like the pre-production turret, the production turret was also produced by Krupp. Its layout was mostly the same as the previous type, but it was much easier to produce.

The sides remained 80 mm thick but were sloped at a less-extreme angle of 20 degrees to make room for the commander, enabling the removal of the bulge in the side. The roof was still comprised of three separate plates, but this time they were all 40 mm thick from the start. The front roof plate was angled at 78 degrees, the central plate was mounted horizontally and the rear plate was angled at 82 degrees.

The armor thickness of the Tiger II’s production turret. Note the thicker, flat front.

The front of the turret was completely redesigned. The 100 mm thick, curved front plate on the pre-production turret was replaced by a 180 mm thick flat piece of steel sloped back at 10 degrees. In front of this and protecting the gun was a large bell-shaped gun mantlet.

The rear remained 80 mm thick, but no longer had a removable section. Instead there was a hole covered by a hatch, through which the gun could be removed.

The first production turret was fitted to the 51st Tiger II made, and continued in use for the rest of the Tiger II’s production run.

News

The Hanging Temple: China’s 1,500-Year-Old Cliffside Marvel of Faith and Engineering

The Hanging Temple: China’s 1,500-Year-Old Cliffside Marvel of Faith and Engineering Perched precariously on the cliffs of Mount Heng in Shanxi Province, China, the Hanging Temple, also known as Xuankong Temple, Hengshan Hanging Temple, or Hanging Monastery, is an architectural…

The Willendorf Venus: A 30,000-Year-Old Masterpiece Reveals Astonishing Secrets

The Willendorf Venus: A 30,000-Year-Old Masterpiece Reveals Astonishing Secrets The “Willendorf Venus” stands as one of the most revered archaeological treasures from the Upper Paleolithic era. Discovered in 1908 by scientist Johann Veran near Willendorf, Austria, this small yet profound…

Unveiling the Maya: Hallucinogens and Rituals Beneath the Yucatán Ball Courts

Unveiling the Maya: Hallucinogens and Rituals Beneath the Yucatán Ball Courts New archaeological research has uncovered intriguing insights into the ritual practices of the ancient Maya civilization. The focus of this study is a ceremonial offering found beneath the sediment…

Uncovering the Oldest Agricultural Machine: The Threshing Sledge’s Neolithic Origins

Uncovering the Oldest Agricultural Machine: The Threshing Sledge’s Neolithic Origins The history of agricultural innovation is a fascinating journey that spans thousands of years, and one of the earliest known agricultural machines is the threshing sledge. Recently, a groundbreaking study…

Nara’s Ancient Sword: A 1,600-Year-Old Protector Against Evil Spirits

Nara’s Ancient Sword: A 1,600-Year-Old Protector Against Evil Spirits In a remarkable discovery that has captured the attention of archaeologists and historians alike, a 7.5-foot-long iron sword was unearthed from a 1,600-year-old burial mound in Nara, Japan. This oversized weapon,…

The Inflatable Plane, Dropped Behind the Lines for Downed Pilots

Experimental The Inflatable Plane, Dropped Behind the Lines for Downed Pilots The Inflatoplane from Goodyear was an unconventional aircraft developed by the Goodyear Aircraft Company, a branch of the renowned Goodyear Tire and Rubber Company, also famed for the Goodyear…

End of content

No more pages to load